Phase 1

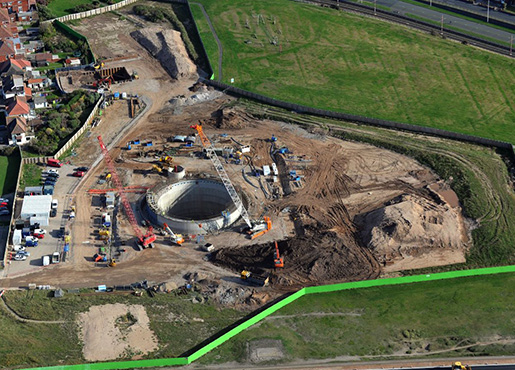

Ward & Burke were contracted for the design and construction of a 30m diameter caisson and interconnecting pipework. Our involvement included all permanent and temporary works design and the project was delivered with great success. The sinking of the caisson was undertaken and managed directly by Ward & Burke operatives and engineers.

The Anchorsholme Park Detention Tank, led to Ward & Burke being shortlisted for two awards at the 2016 Ground Engineering Awards in London; Contractor of The Year, and the Health and Safety Award, winning the latter.

A number of innovative techniques were used to construct the caisson with particular attention on the management and coordination between the permanent and temporary works throughout the project.