Works included design and construction of;

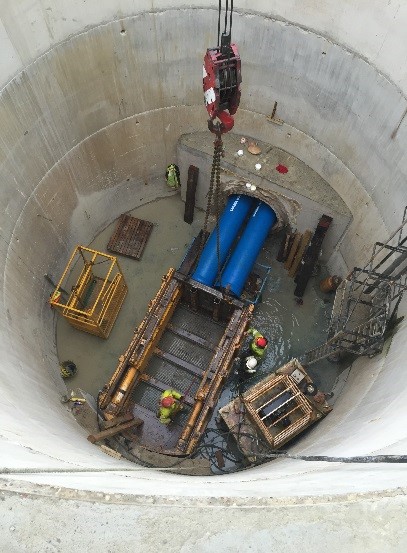

- 2No. 8m diameter Launch Shafts 11m and 20m deep respectively.

- 2No. 7m diameter Reception Shafts 10m and 21m deep respectively. (All shafts were constructed as a caisson and sunk to formation)

- 300m tunnel using an AVN 1600 (100m under the M20 motorway and 200m under the River Medway and adjacent Network Rail lines). 1600mm ID concrete jacking pipe installed.

- Bottom screed and carrier rails along full length of tunnels to allow installation of twin 600mm ID ductile iron pipes, with use of hydraulically operated jacking frame.

- Bulk headwalls/thrust blocks and pressure test pipelines.

- Grouting of the annulus between concrete jacking pipe and ductile iron pipes along full length of tunnels.